I started building CNC machines long ago. My first inspiration came from Bruce Shapiro’s eggbot. I tried a few variations of it and even the board from evil mad scientist.

One day my friend Joe told me he was interested in CNC. I told him I had played with it for years but never seriously committed to it. We decided to build one at work over lunch. Doing a little bit each week. We only have one day a week we can get together

It is so close but only using 3 or 4 hours a week has been a little limiting. We got the x and y done and some tuning so it can now plot pictures using a sharpie. We just have to finish the z axis

I recently completed a similar machine at home using some old printer parts and a dremel.

The base is a side panel from a computer UPS. A dot matrix printer gave it life to become the main carriage and the rails from an antique laserdisc player completes the z axis

It’s driven by an arduino mini running GRBL 0.8c.

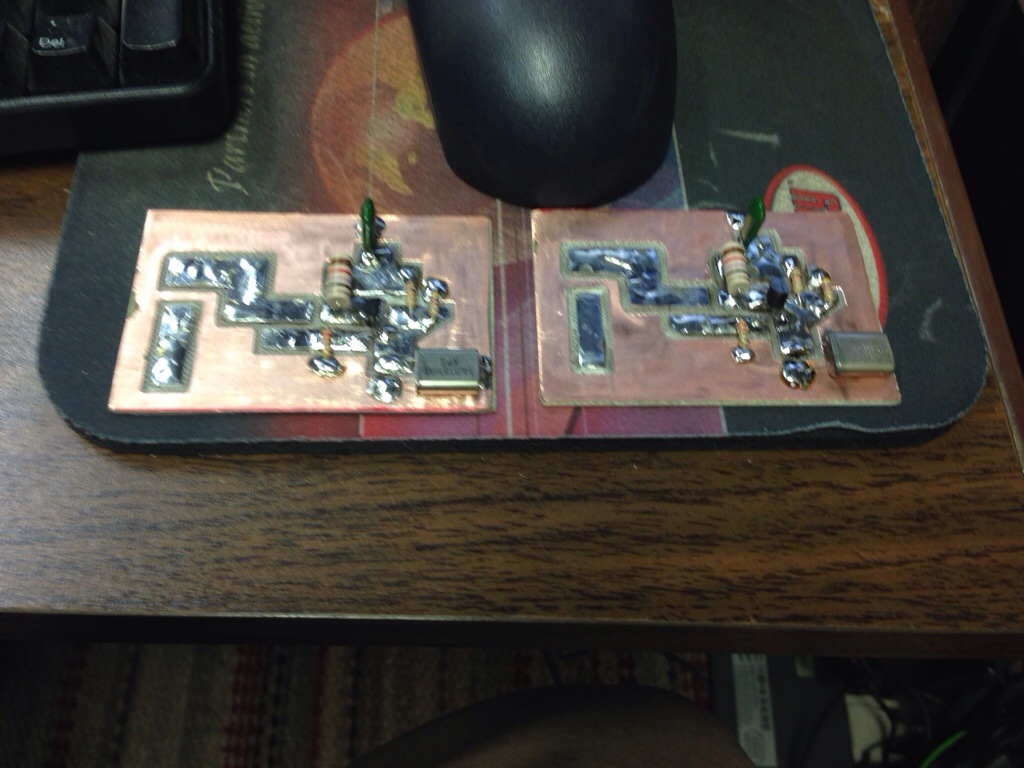

There are 4 PIC 12c508 support chips. 3 handle the step direction deciding for the three axis and the 4th converts the z axis set and directions signals the a relay closure to operate a diode laser for simple engraving tasks.

I used 6 toshiba h bridge chips to drive the bipolar steppers. There are 2 solid state relays one for the dremel and the other is for a shop vac. An old compaq notebook supply runs everything.

Spindle codes control the dremel and flood coolant commands control the shop vac

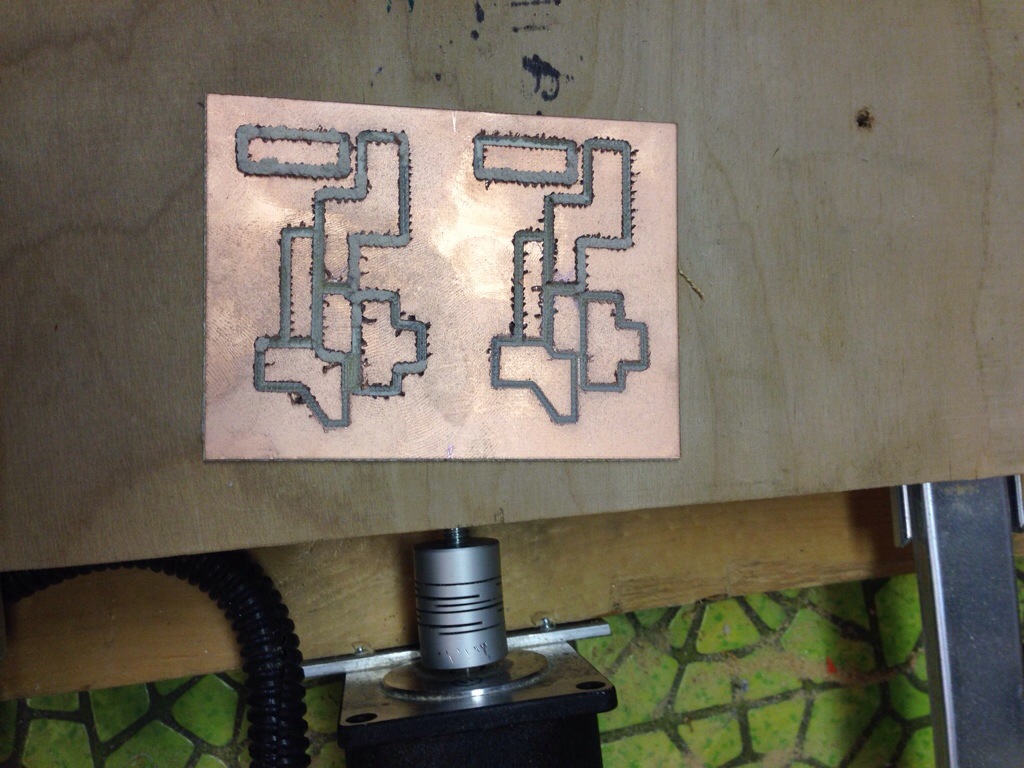

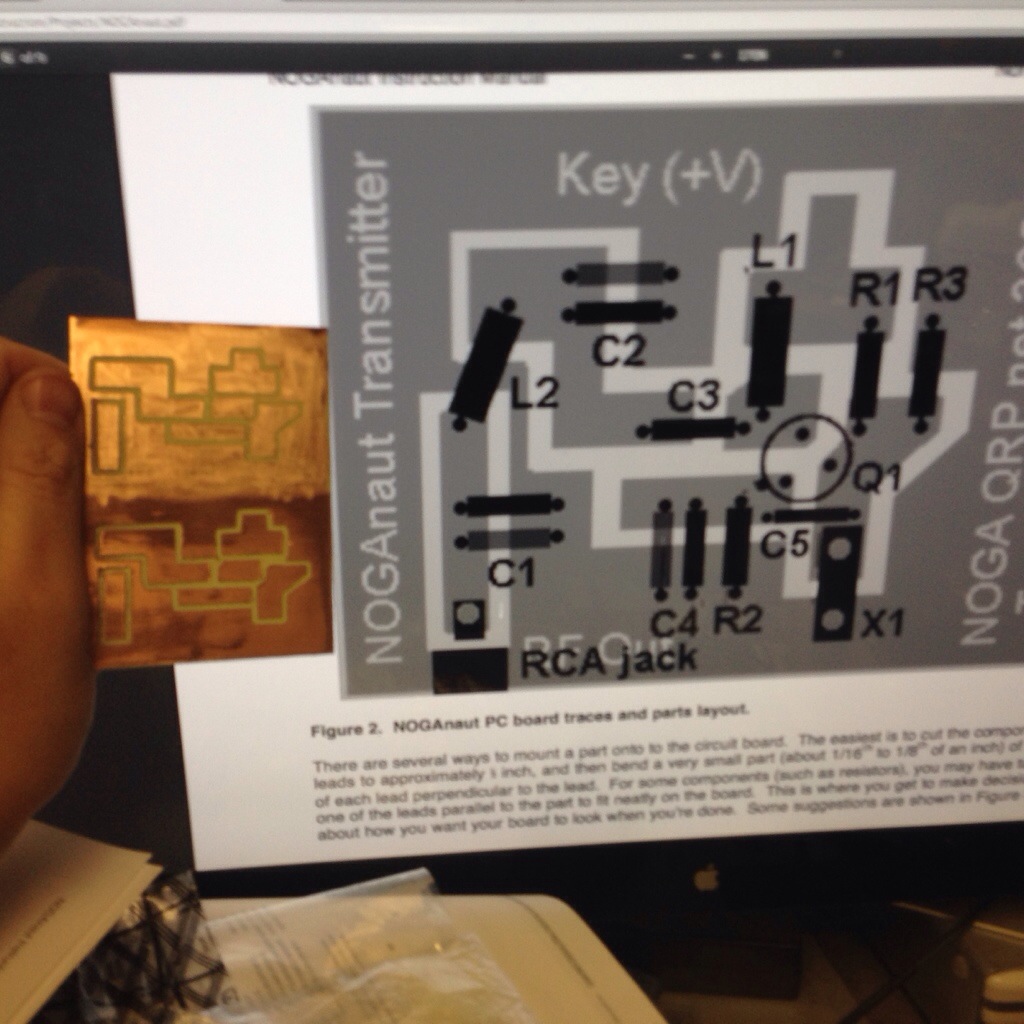

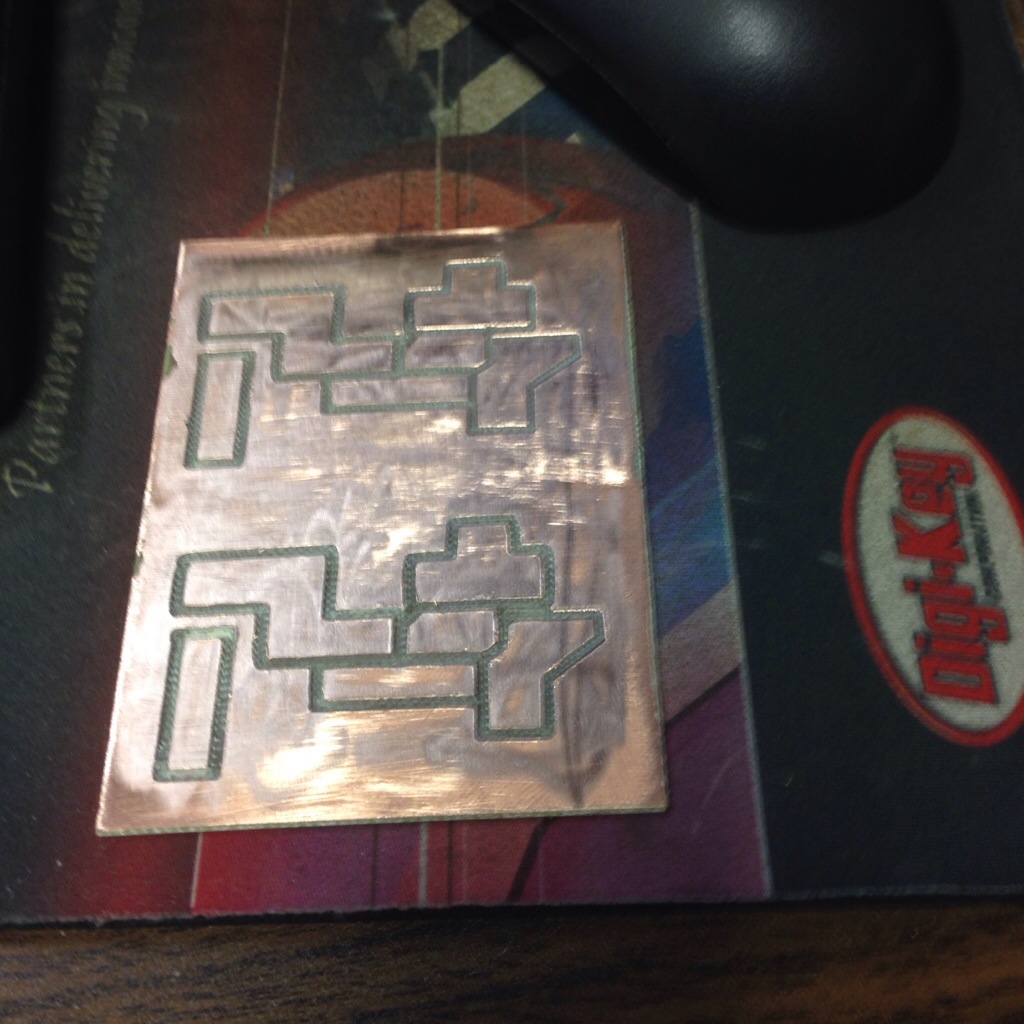

The first few pieces came out pretty good

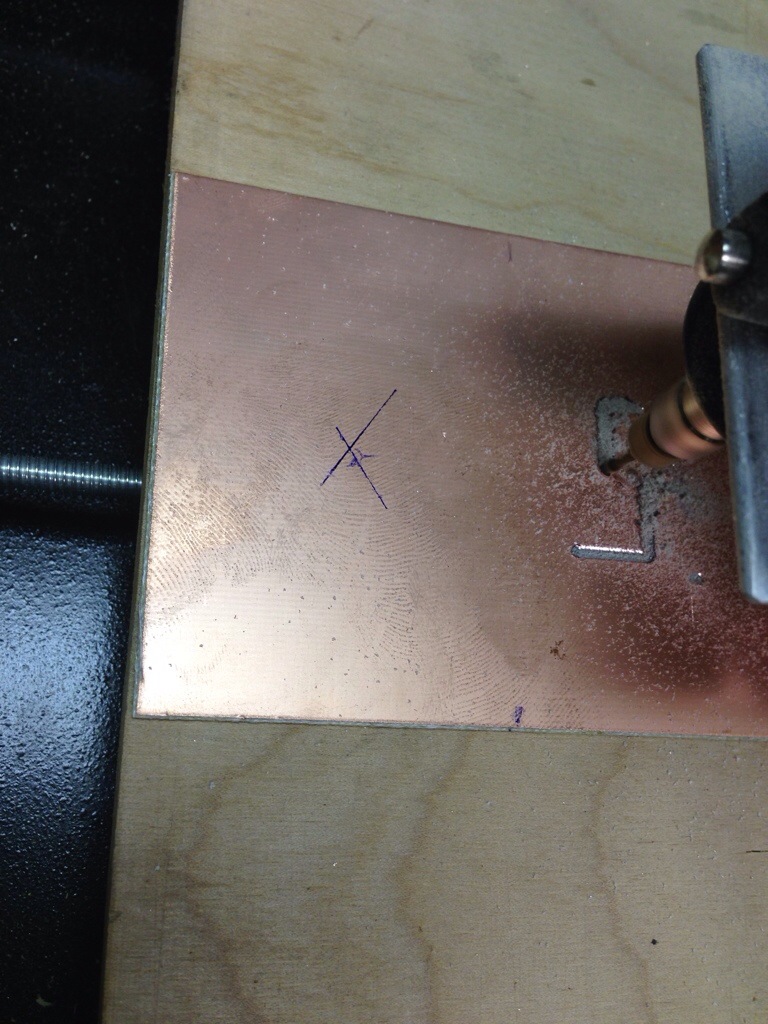

I used a dial indicator in place of the dremel initially to level the table. I managed the get it to within .008 in. It’s not really crooked but cupped slightly in the center

So far that hasn’t been a problem

Here are the first tries….

I was pretty happy with the results.